About us

We’re passionate about Alpaca Fibre

Verlore Vallei Alpacas is a dedicated alpaca breeding facility with a passion for Alpaca Fibre, located in a secluded valley beside the Elands River. The herd is raised on a sixth-generational family farm, where the term ‘eco-friendly’ anything is a bit of a joke, bacuse we have never been ‘non-eco-friendly’… Escom has never even had any presence here! Load-shedding? What’s that?

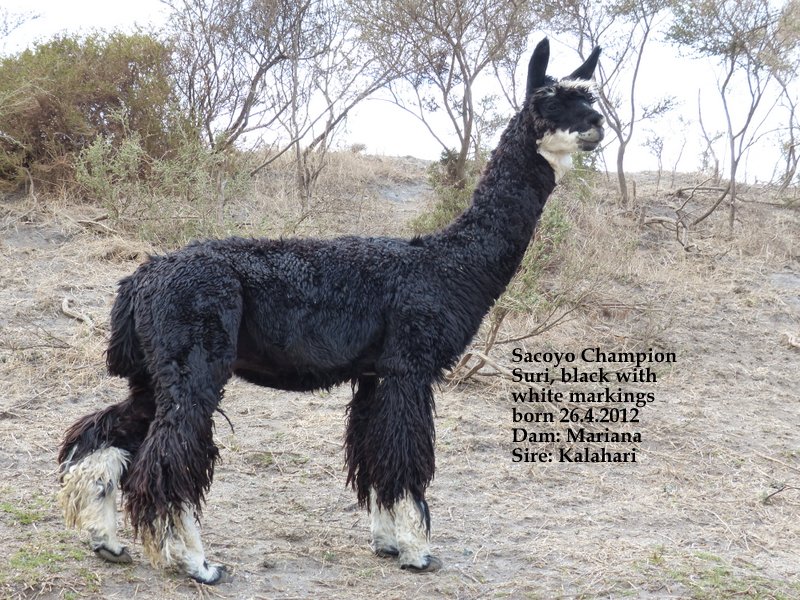

Dedicated Suri Alpaca Breeders

We are dedicated to breeding superior Suri and Huacaya alpacas – with a special emphasis on promoting and preserving the rare Suri. We are one of the very few suri alpaca breeders in South Africa. Breeding decisions are mainly aimed at combining the best possibilities in positive inheritable genetic traits, and sensory, hands-on – striving for perfect conformation, lustre, lock and crimp quality, low microns, limited guard hairs, and above all, retaining the lovely and diverse natural colour range alpacas are known for. The end-focus is achieving perfect fibre quality! Did I mention we’re passionate about alpaca fibre!?!

We understand the importance of all-white fibre to facilitate processing alpaca fibre in large mills, but as preventing the loss of colour genetics represents a major part of our objective, we process all our own fibre, and as a result we are planning on setting up our own mini-mill, the mill building being well under way already, but as we are doing everything cash – see the reasons below – this is a very slow process.

But the mill is an absolute must to process even limited quantities of special colour batches, and we are serious about putting alpaca fibre within reach of all spinners and handcrafters, in a sustainable way. This is also essential when processing Suri fibre, as these beautiful, spirited and regal animals are still very scarce in South Africa, and processing their fibre certainly poses a challenge and a hands-on approach.

There are no mills geared up to handle Suri fibre in South Africa, and as a result, many would-be breeders are passing up the opportunity to raise these feisty yet elegant animals, because they just don’t know what to do with the highly valuable fibre, for which there is NO FAIR MARKET in South Africa! Breeders are paid a pittance, the fibre is then carted off overseas, turned in super-high-end yarns and garments only affordable by the super rich and Royalty! As a passionate spinner and fibre crafter, this is utterly unacceptable to the stud owner!

We are one of the largest active breeders of Suri in South Africa, and we want to increase the numbers of these exceptional animals, even import some more bloodlines! Most of all, being absolutely smitten by their fibre, more animals will ensure more fibre, so it is just natural that we would want to change the way their fibre is handled too! And we have the PERFECT SOLUTION TOO!

But a passion for breeding exceptional and scarce animals for their truly exceptional fibre, does hold some serious drawbacks! We breed for the love of the fibre, and would like to process this ourselves to keep costs affordable to everyone, not just the very rich.

But there is a catch to that too! Processing all of this fibre manually requires loads of time and effort, which, when converted to staff salaries, makes the fibre unaffordably expensive… And besides extra staff, you still require loads of very expensive equipment, drumcarders, hand combs, spinning wheels, hackles, blending boards…!

Making a living out of what we love most, can be tricky at best. You need to do a whole lot of what you love to make a living out of that…! Handcrafting is really satisfying, yes, but it is also an awfully slow process… And to balance the time you’ve invested in it, against the income you earn from it, well, that’s a very tricky issue… And eventually, not very inspiring, or just downright disheartening…!

If you were to charge the true value of what you’ve made based on the actual time you spent on it, you will never be able to sell it, so you have to sell it well below what you actually put into it. For a small business, this spells instant doom… The economic system we live in today has been hijacked and rigged to ensure people are always caught up in 9-to-5 jobs, battling to make ends meet… And hobbies remain just that, a luxury to be pushed towards the backburner… Something we would like to do, but we just don’t have the time or even the money to do it…

Yes, we could go and apply for funding the usual way, where the banks would charge an immense amount of extra interest over time, which would mean the prices we would have to charge for the finished product would have to be inflated severely to cover that too…!

Inflation is a vicious cycle – businesses owe the banks huge amounts of money and interest, but they need money to be able to continue running their business too. So, they need to borrow ever more money, eventually turning to the share market (because that’s where they have been herded to from day one) and sell shares in their business, but the investors want a profit at the end of the year, the banks still want their money and interest, so companies have to push up their own prices, cut back on salaries, pay off employees, drop quality standards, skimp on raw materials, lose clients, eventually sinking their business, and so this vicious process continues…

The really dark end of this process, all those companies who are failing and falling by the wayside, because let’s face it – this process was set up with the intention to fail – are guzzled up by those investors who knew it was just a question of time. To them, it’s just another game to feed their greed! Remember, they look at the EXIT STRATEGY even before the first investment payment is made! Look at the small print, and lately it’s not even in small print anymore…! They are quite open about it!

No real passionate CREATIVE person would ever want to start a business with the idea of abandoning it after 3 to 5 years, either willingly or forcibly!!!

The entrepreneur would do all the hard work, shed their blood, sweat and tears, while their fat-cat investors cream off the profits… When the company fails, not if, they step in and buy up the company for a few cents to the dollar, incorporate it into their ever-expanding corporate structures, or dissolve it if they didn’t like that particular low-profit structure, because they have unlimited bank accounts from playing this game for decades, some even centuries…

Verlore Vallei Alpacas & Fibrecraft refuses to get on that hamster wheel!!!

Crowdfunding to put up the Mini Mill

We have started a Crowdfunding drive, as this is the only way open to humanity to facilitate a free future! Please support us! https://gogetfunding.com/verlore-vallei-alpaccas-eco-mini-mill/

Verlore Vallei Alpacas have issued our own ‘in-store currency’ known as Clan Coins. If you donate 5 USD, you will receive 5 Clan Coins in credit to spend in our online store once the mill is up and running. And if you really can’t wait, you can get hand processed fibre in exchange at any time! To make it fair as the currency is just another one of those items being manipulated to make some people rich and sink others, the ZAR value at the date of the donation will be used.

This will be of exceptional value to other alpaca breeders and owners of small fibre herds in or near Gauteng, as they can cash in their Clan Coins on having all their own fibre processed in the mill once it is up and running!

I truly believe this way of crowd funding is the answer to many people’s Creative Dreams!

Mini Mill planning

Verlore Vallei Alpacas’ motto: “Let’s not breed to suit the mills, let’s put up mills to suit our breed!”

The Mill equipment is not available in South Africa, and needs to be imported from Canada. Despite many ups and downs, nearly fatal accidents, lockdowns and losses, the objective to realize a decade-old dream of establishing the MiniMill, Training Centre and Studio that’s been percolating on the backburner for the last decade already, has never changed.

The Mini Mill will make it possible to process quantities greatly exceeding that which a few women can do in a month, in fact, doing so in a single day, yet it will be done the same way, with eco-friendly scouring products and no harsh chemicals, using very little water, at a fraction of the quantities commercial mills are using. And still not on a commercial scale, so the ecological impact will be minimal! A mini mill compares to an industrial mill the way hand processing compares to a mini mill! So, it is in that sweet spot where it is still sustainable, but certainly not a parasite on the environment! Corporations bypassed this stage, because they were always just pushing for more profits, where the real emphasis should have been on finding BALANCE!

The fibre and yarns processed by the mill will in turn become available for purchase at highly affordable prices. To date, hand processed alpaca products were logically expensive due to the time invested in processing it, and products processed abroad had to be imported and these were pricey. Some locally processed yarns are available, but demand greatly exceeds supply, and healthy competition has always been good for NORMAL business. Corporate greed calls for limiting everything, and driving up the prices for increased profits, I want the opposite so our world can return to normal! That’s another reason my business plan does not meet the average satanic ‘investors’ idea of a sound investment where they want to be able to squeeze out more blood from their pound of flesh invested…

If we can succeed setting up the mill with funding from friends and interested parties, we will NOT be shackled with high-interest repayments for the next decade or so, which would just be pushing up prices. The mill would be paid for, meaning everything could be sold at much lower prices, basically cost plus administration charges. Which by the way, boils down to a ‘non-profit’ venture!

We will be sourcing the Mill equipment from Belfast Mini Mills. Visit their website to get a better idea of what we are planning. https://minimills.net/start/ Using this as a search term in YouTube will provide a number of videos to serve as an example of just what we have in mind!

OUR OBJECTIVES

- Promoting the breeding of Alpacas, and preservation and breeding of Suri in particular.

- Preventing the loss of colour genetics, in both Suri and Huacaya.

- Producing quality alpaca fibre, with perfect lock, lustre and crimp quality at the lowest possible microns, to obtain the true softness of natural alpaca fibre.

- Processing our own fibre to be able to breed all colours and all patterns, no matter how small the various coloured batches turn out to be.

- Creating a socially responsible and sustainable business, in sync with the environment.

- Creating employment for the local community, teaching skills in this sector of the industry.

- Providing our customers with 100% natural colour fibres with incredible fineness and handle, and the advantage that only true eco-friendly fibres can offer.

- Dyeing of fibres, where projects require colour other than nature’s alpaca palette, is mostly done with natural dyes or with ecologically-safe Oeko-Tex compliant dyes.

- Raising awarenes of the importance of saving the genetic pool of the many endangered rarebreed fibre animals all over the world, before it’s too late.

- Teaching hands-on skills to a generation that has mostly lost it’s connection to Mother Earth, and no longer knows the pleasure and feeling of accomplishment one can get from creating something tangible using your hands. This includes animal husbandry, raising fiber animals among others, living a sustainable life, shearing and processing fibers manually, spinning, weaving, lacemaking, knitting, crocheting, felting, sewing, and even food preservation.

Shearing:

We shear our animals once a year, where they are restrained for the shortest possible period of time, to ensure they don’t hurt themselves or their shearer.

Despite some horror stories spread around by people intent on gaining followers of their monetized You-Tube content, based on blatant lies coated in bits of truth – yes alpacas do not like being restrained any more than a toddler sitting still for a filling or tooth extraction at the dentist – alpacas, just like sheep, NEED to be sheared once a year! This is for their own health and comfort!

Who after all in their right senses would like to parade around in a fur coat in the hottest part of summer!?!

Dyed fibre:

For those moments in life where a real splash of colour is needed, it is always possible to lend a helping hand with lovely natural dyes like indigo, madder and marigold, to name just a few. For more repeatable colour results, acid dyes can also be used.

Fibre processing: Raw fiber is first skirted, picked, then washed, dried, and picked again. Then it can be carded on drum carders, hand carders, or combed into top. These processes are very time-consuming, as it is all done the old-fashioned way, by hand.

The mill process will be similar, but will make it possible to process quantities greatly exceeding that which a few women can do in a month, in fact, doing so in a single day, yet it will be done the same way, with eco-friendly scouring products and no harsh chemicals, using very little water, at a fraction of the quantities commercial mills are using.

Hand-combing to prepare top

Here, the washed alpaca fibre was combed and then dizzed to create this lovely top in a very light cream fawn – ready for spinning into next-to-skin garments. Top is available in all of the natural alpaca colours, and subject to your needs, can be overdyed and blended in a range of colours too.

Top is literally the cream of the crop, and it is worth noting that about half the weight in fibre ends up as wastage when top is combed, as every tiny bit of anything that doesn’t conform to the perfect longest fibres are removed. You are literally left with the best of the best, the top! So now you know why Top also comes at a top price!

Even with the mini mill eventually being established, top will still be processed manually, allbeit based on milled roving, as we will not be using the harsh chemicals and hight temperatures used commercially to eliminate VM. That’s what makes hand-processed top so different from commercial top, the fibre hasn’t lost it’s characteristics! Not to mention there are NO harmful chemical residues that could be absorbed through the skin when the final garments are worn, or worse still for spinners, while the fibre is being spun!

Dyeing, Blending and Carding

Here, alpaca was dyed and blended with natural white alpaca and silk for special effect. Then it was rolled into a rolag, ready to spin. It can also be spun straight from the carded cloud, as can be seen below.

Madder-overdyed, hand-carded royal alpaca and silk fibres, such a delight to spin, it was easy to forget to move the bobbin spacer…

A word of caution – if you want to order dyed and blended fibre, please order enough for your project from the start, as dye lots and blending WILL differ!

Natural dyes like madder root has a mind of it’s own… And even the natural alpaca colours differ in different parts on the same animal, and also becomes darker year after year, so the same animal’s fibre will not be exactly the same next year!

Want to know more about me?

For more information on what else I have in store for you, refer to my pages for more information, https://verlorevallei.com/all-about-alpaca/ or contact me https://verlorevallei.com/contact/!

Follow me on our Facebook page https://www.facebook.com/Fibrewitch to stay up to date with tips, good video suggestions, our latest art yarns, fibre specials, bats and rolag packs! Many of which never make it to the website! What’s more, you will get a heads-up when new Majacraft stocks are about to arrive in South Africa, so you can have first dibs! Stock seldom makes it on to the website! I am also working on ‘How-to videos’ on numerous fibre related subjects and life on the farm, which will be posted on Facebook first, unless you follow me on YouTube already, in which case you will be notified. http://www.youtube.com/@VVAFibrecrafts

You can also join my Whatsapp group, where special fibre blend drops or VVA You Tube videos will be announced from time to time – https://chat.whatsapp.com/FWE0y6MTj0uEekmFSm3g6t

I usually also have the following natural alpaca fibre colours in stock, as we have animals in all these colours: Natural White, Light Fawn, Medium Fawn, Dark Fawn, Light Brown, Medium Brown, Dark Brown, Black, light Silver Grey, Medium Silver Grey, Dark Silver Grey, Light Rose Grey, Medium Rose Grey, Dark Rose Grey.

A section for dyed fibres will also be added. You are sure to find something to your liking! I am always open to suggestions, and happy to help with custom orders. I also stock fibre of other sheep breeds that are sourced from the UK from time to time.

Please leave a comment, I’d love to hear from you!